SQF Tips: How to Make Your Food Fraud Program Compliant

By Anthony Camperone, Technical Development Manager, SGS North America, Inc.

Food fraud has been a concern for hundreds of years, dating back to the 1800’s, most notably the 1858 Bradford Sweets candies poisoning in Bradford, Yorkshire. The price of sugar was so high that the material had to be brought into the UK from the West Indies. This price increased the likelihood that alternatives would be used to reduce the cost. The main alternative used at this time was ‘daft,’ which typically consisted of a mixture of limestone and plaster. This material, at the time, was perfectly safe. Unfortunately, due to a mistake at a pharmacy, 12 pounds of arsenic was improperly labeled as daft, which then resulted in more than 200 illnesses and 20 deaths.

Fast forward to present day and it is estimated, per the FDA in 2021, that the cost of food fraud can reach upwards of $20 billion globally. So how can suppliers utilize SQF to protect their products? It all starts with a thorough vulnerability assessment.

A thorough vulnerability assessment which organizes a list of all ingredients, raw materials, finished product, packaging, and labels serves as a guide. Many sites find the use of an ingredient database or government tracking website useful in identifying potential threats.

To be what I would consider thorough, we must get away from the comment, “Well we get it from a reputable supplier, so we don’t have any risk.” This couldn’t be further from the truth. It’s not only whom you purchase the material from, its where the material or materials originate from. Although a raw material was purchased from Company or Broker X, certainly does not mean the material was manufactured or even handled by Company or Broker X.

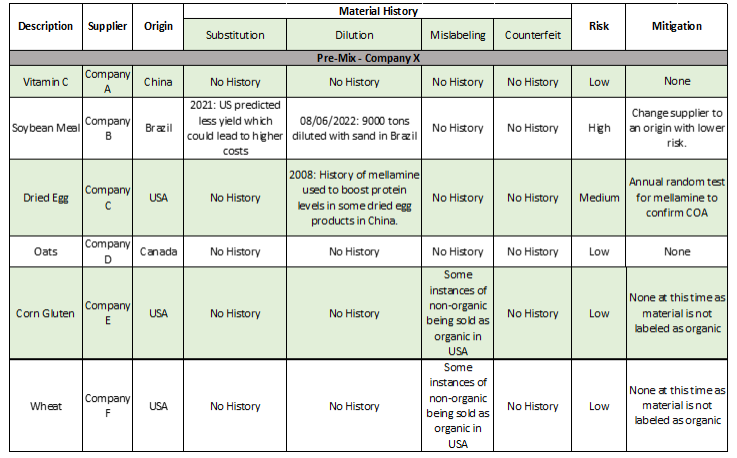

Let’s look at an example of a multi-component pre-mix that consists of vitamin C, soybean meal, dried egg, oats, corn, gluten, and wheat.

The above example does not consider the components of the pre-mix and does not assess that actual vulnerability of the materials.

The above is an example and does not indicate actual data

The above example provides a detailed assessment that includes historical data of food fraud incidents for each component. This type of assessment will give suppliers an adequate sample size of data to determine if any mitigation strategies are required to ensure their products have a reduced risk of food fraud. Risk mitigation strategies can vary based on the material and types of risk associated. These mitigation strategies can include lab testing, visual inspections, and changes to the supplier.

There are a multitude of risks associated with food manufacturing and the best defense we can have is to fully understanding our processes and supply chain. This takes time to gather, but once we have the data, we can make informed decisions on how to protect our products.

The SQF Program addresses Food Fraud in Section 2.7.2 requiring the site to identify their vulnerability to food fraud through all inputs including mislabeling, ingredient substitution, and counterfeiting.

You can find a helpful glossary of terms and Implementation & Audit Guidance in the free downloadable Food Fraud Guidance Document found here.

There is a helpful chart with Records, Interviews and Observations (RIO) to assist in preparing, implementing, and reviewing the site’s food fraud program.

Recent Blog Posts

With Edition 10 audits arriving as early as Jan. 2, 2027, sites that start closing gaps today will walk into their audit with far more confidence than those scrambling at the end of 2026.

SQF Food Safety Code Edition 10 is now available, and it marks more than a routine update to the Code.

As we move toward the launch of SQF Edition 10 in early March, one message is clear. Food safety is no longer evaluated only through programs, procedures, and records.